Heavy Duty Waste Balers

Heavy Duty waste balers

Our range

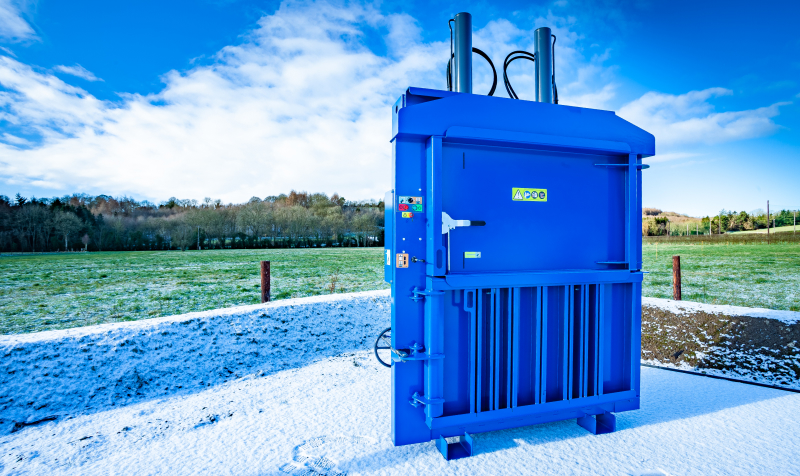

We know that some recyclable materials can be a bit tougher than others. That’s why we have a specialist range of heavy duty waste balers to deal with trickier items such as mixed rigid plastics, aluminium drinks cans, paint tins and plastic bottles, as well as more straightforward cardboards and paper. However complex your waste streams we’ll work with you to convert these tough materials into secure, sturdy bales. And like all of the other waste balers within our extensive range, all are available to rent or purchase outright. Simply tell us what works best for you.

Waste balers

What is a heavy duty waste baler?

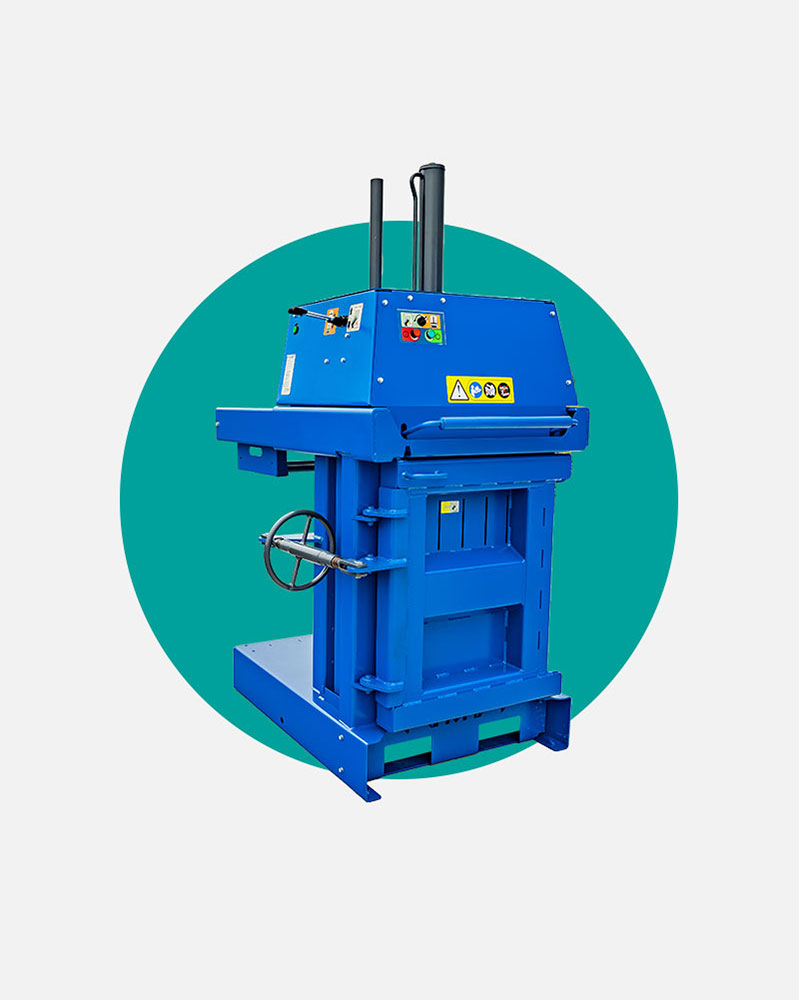

A heavy duty waste baler is a more robust version of a standard vertical baler, engineered specifically to handle tougher waste materials. These machines are built with additional reinforcement and enhanced structural strength, making them ideal for compacting items such as mixed rigid plastics, aluminium cans, paint tins, and dense plastic bottles—alongside the usual cardboard and paper.

To tackle these more challenging materials effectively, RWM heavy duty balers feature a full stroke ram, ensuring maximum compaction with every cycle. They’re also equipped with additional rows of retaining teeth, which help grip and hold material in the chamber, reducing the spring-back effect often associated with springy or bulky recyclables. The result? A more compact, stable bale and a more efficient baling process overall.

Whether you’re renting or buying, our HD balers are a smart solution for businesses needing extra muscle in their waste handling

By input

What materials does it bale?

RWM heavy duty balers are designed to bale a wide range of materials, including mixed rigid plastics, aluminium cans, plastic bottles, paint tins, cardboard, and paper.

Discover more

Benefits of a heavy-duty waste baler

01

Built for Tougher Materials

Engineered with reinforced construction to handle dense, awkward, or abrasive recyclables such as semi-rigid plastics, aluminium cans, and paint tins.

02

Maximum Compaction

Full stroke rams ensure every cycle delivers consistent, high-pressure compaction—resulting in tighter, heavier bales.

03

Reduced Spring-Back

Additional rows of retaining teeth help prevent material rebound, improving loading efficiency.

04

Versatile Waste Handling

Capable of baling both complex and straightforward materials—from plastic bottles and cans to cardboard and paper.

05

Space-Saving Design

Despite their power, RWM HD vertical balers maintain a compact footprint, making them suitable for tight or restricted workspaces.

06

Flexible Purchase Options

All machines are available to rent or buy outright—making it easy to find a solution that suits your budget and business needs

Featured product

RWM 500

Looking for a robust mill size baler? Commonly used as a cardboard or plastic baler for packaging waste, this tried-and-tested machine is actually suitable for an array of dry recyclables. With a large loading aperture it can easily handle large volumes of waste, and will produce bales that maximise transport efficiencies and load capacities.

Cardboard

Plastics

Paper

Film

"SWM are committed to safety, which is one of the key factors in sustaining relationships with suppliers and contractors – that’s why Riverside Waste Machinery Ltd has been servicing our internal balers successfully for a number of years. We recently needed to purchase a tipping skip and – despite not being advertised on their website at that time – Riverside happily provided a quote, which we accepted, and delivery was made promptly after."

Rebecca Howlett

SWM international