RWM 40 PET Multi

Product Overview

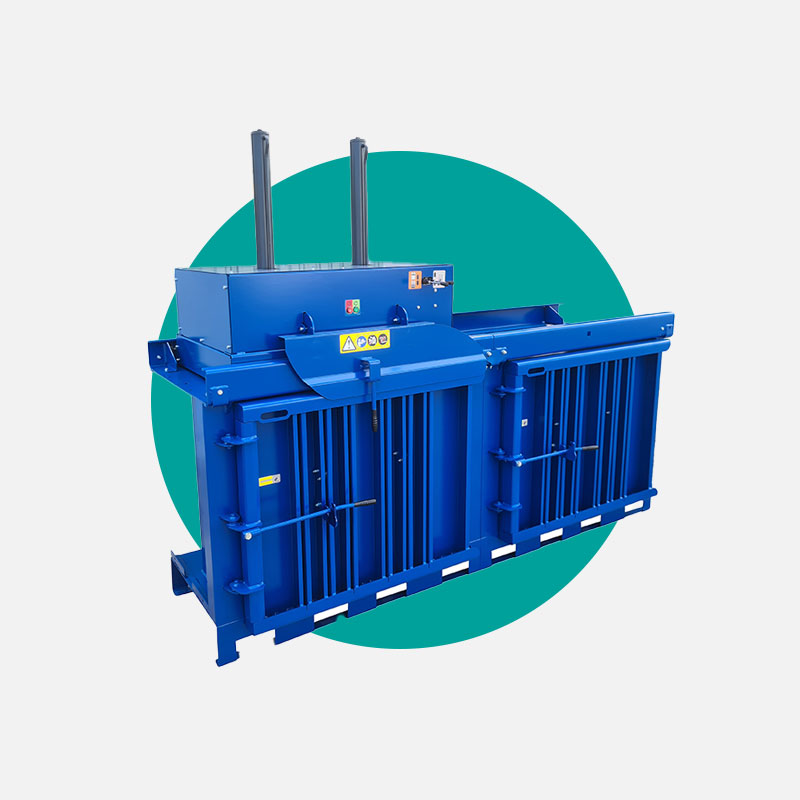

RWM 40 PET Compact Waste Baler

The RWM 40 PET is a compact, top-loading waste baler specifically engineered for processing PET bottles, aluminium drinks cans, and cardboard vending cups. It’s particularly effective for baling plastic bottles with their lids still attached, thanks to its integrated spike perforator compaction head. This clever feature pierces the bottles during the baling cycle, allowing trapped air to escape so the material can be properly compacted.

Equipped with a full-stroke ram, the RWM 40 PET ensures consistent and thorough compaction of even stubborn recyclables like uncrushed bottles and cups. Its upright, top-loading design makes it easy to load loose bottles, cans, or cups directly into the chamber, keeping the baling process clean and efficient.

Built with a rugged, durable finish, the machine is suitable for both indoor and outdoor installation—ideal for sites with limited space.

Perfect For:

-

PET Bottles

13T

Press force

562kg

Machine weight

25 sec

Cycling time

Technical specification

Pressing force

13 tonnes

loading aperture

700 x 500mm

bale weight

up to 40kg

noise level

68 decibels

machine weight

562kg

cycle time

25 seconds

power supply

16amp 2.2kW-230V-50Hz

overall dimensions

2342 x 2050 x 851mm

(H x W x D)

Key Features

This robust and versatile baler is equipped with a unique piercing compaction head, eliminating the need to remove bottle caps before baling. It features a generous 700 x 500mm top-loading feed aperture. A 30-litre liquid collection tray with tap helps manage residual fluids, making it ideal for handling bottles, cans, and cups.

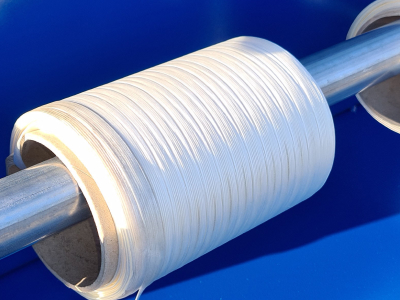

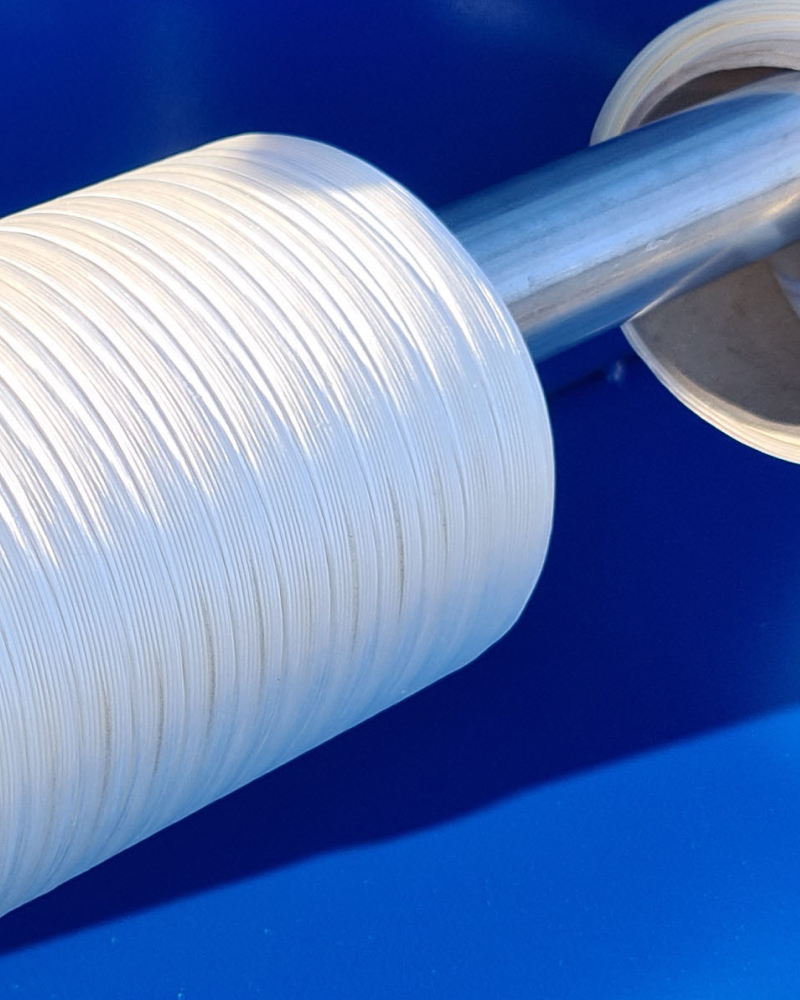

Built for both indoor and outdoor use, the RWM 40 PET operates on standard 16-amp single-phase electrics and delivers up to 13 tonnes of compaction force. Key features include a full-stroke ram for effective crushing, integrated retaining claws to minimise material spring-back, dual baling tape ties for secure bundles, and a free bale trolley for easy handling of the bales.

"Our employees love how simple the machines are to operate – the wires can be fed in with no problems and the bales are easy to tie, creating a robust product for us to sell on."

Adrian Johnson

Services Manager, F. Duerrs & Sons

Discover more

Related consumables

12 month warranty

For parts & labour as standard

20+ years experience

Supplying robust waste machinery

Rated 5/5 on Google

Great customer service

Buy, rent or hire

On all machines

Help & Support

Aftersales care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.

People also liked...

Other multi chamber balers

If your site space is limited and you need a waste baler with a small footprint, or you’re handling relatively low volumes of recyclables so don’t yet require a high capacity baling press, then one of our compact waste balers could be perfect for you.