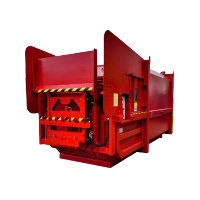

RWM RPW30

Product Overview

About the RWM RPW30 Compactor

If your business produces a significant amount of general or wet waste, the RWM RPW30 portable compactor can make managing it far more efficient. Unlike a standard skip or open container, the RPW30 compresses waste at source, allowing you to store more in a smaller space. This means fewer collections, lower costs, and a cleaner, more organised site.

The RPW30 is fully enclosed, designed to keep liquid and odours under control. When collected, the entire unit is taken away, emptied, and then returned to your site. Your waste is transported securely – no leaks, no mess.

Perfect For:

-

General Waste

-

Wet Waste

33T

Compaction force

5.5kW

Motor

56 sec

Cycling time

Technical specification

Machine Capacity

25m³

Compaction force

33 tonnes

Loading aperture

1500 x 1380mm

(W x L)

Loading height

1500mm

Cycle time

56 seconds

Motor

5.5kW

Overall dimensions

2810 x 2410 x 6800mm

(H x W x L)

12 month warranty

For parts & labour as standard

20+ years experience

Supplying robust waste machinery

Rated 5/5 on Google

Great customer service

Buy, rent or hire

On all machines

Key features

RPW30

-

Swing Blade Compaction System – The RPW30 features a swing blade compaction mechanism, making it especially effective for wet food waste. By directing liquid away from the ram cylinders and other hydraulic and electrical components, it helps to protect the machinery and extend its service life.

-

Cost Savings – With higher waste densities, fewer collections are required, directly reducing disposal costs.

-

Improved Hygiene – Enclosed design helps prevent spills, control odours, and deter pests.

-

Environmental Benefits – Fewer vehicle movements reduce CO₂ emissions and support your sustainability goals.

-

Operational Reliability – Built to handle demanding waste streams, the RPW30 is a robust and dependable solution.

-

User-friendly controls – requiring minimal training

-

Flexible sizes and specifications available

Help & Support

Aftersales care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.