Drum & Glass Compactors

Drum & Glass Compactors

Our range

At Riverside Waste Machinery, we offer specialist compactors designed to streamline the handling of two notoriously bulky waste streams: steel drums and glass bottles. Whether you’re looking to reduce the volume of empty beer and wine bottles in a bar or restaurant, or efficiently crush large steel drums in an industrial setting, our robust machines are built to perform — saving space, reducing disposal costs, and improving workplace efficiency. Our range includes high-performance drum crushers ideal for crushing 205-litre steel drums, and compact, easy-to-operate glass crushers that quickly reduce glass waste to a manageable size. Both options are perfect for businesses that need a cleaner, safer and more sustainable way to manage their waste. Explore the features of each machine below to find the right solution for your operation.

Overview

What are drum & glass compactors?

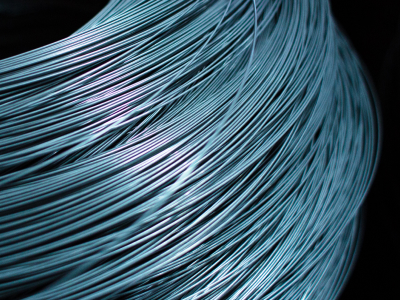

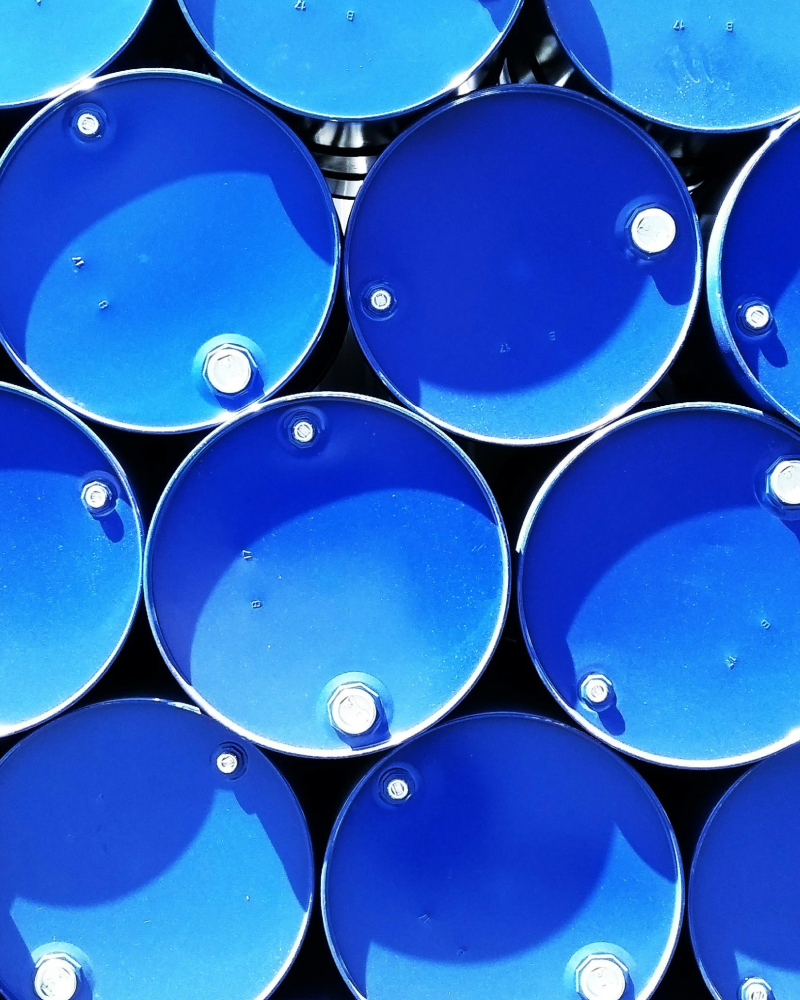

Drum and glass compactors are specialist waste machines designed to reduce the volume of specific waste types — namely steel drums and glass bottles. A drum compactor (often referred to as a drum crusher) is used to crush empty steel drums, typically 205-litre barrels, down to a fraction of their original size. This makes storage, handling and disposal far more efficient.

A glass compactor (also known as a glass crusher) is designed to crush glass bottles — such as wine, beer or soft drink bottles — into small, manageable cullet. This significantly reduces waste volume, minimises handling, and helps create a tidier, safer working environment in bars, restaurants, hospitality venues, and recycling facilities.

Both types of machines are built for durability, safety and ease of use — helping businesses save time, reduce costs and support more sustainable waste practices.

What materials does it compact?

Drum and glass compactors are designed to handle two specific waste streams. Drum compactors are used to crush empty steel drums and oil barrels, typically up to 205 litres in size, making them ideal for industrial environments where metal containers are common. Glass compactors, on the other hand, reduce the volume of glass bottles — including wine, beer and soft drink bottles — turning bulky waste into manageable cullet ready for recycling. Both machines offer a simple, efficient way to deal with otherwise awkward materials.

Drums & barrels

Materials

Glass

Materials

Discover more

Benefits of drum & glass compactors

01

Crushes bulky steel drums

to a fraction of their size, freeing up valuable floor space.

02

Reduces disposal costs

by allowing more drums to be stored and transported in less space.

03

Improves site safety and cleanliness

with enclosed crushing and minimal manual handling.

04

Significantly reduces glass volume

helping to cut down on bin collections and waste disposal costs.

05

Creates a safer, tidier workspace

by eliminating loose bottles and reducing handling risks.

06

Improves sustainability

by producing clean cullet ready for recycling.

Featured

Glass crusher

As with many of our technologies, the primary goal of the RWM Glass Crusher is volume reduction. In fact, with a compaction ratio of 5:1, from bottles to cullet, our clients can reduce the frequency of their glass collections and therefore experience cost savings of up to 80%.

Glass