Multi-Chamber Waste Balers

Multi-chamber waste balers

Our range

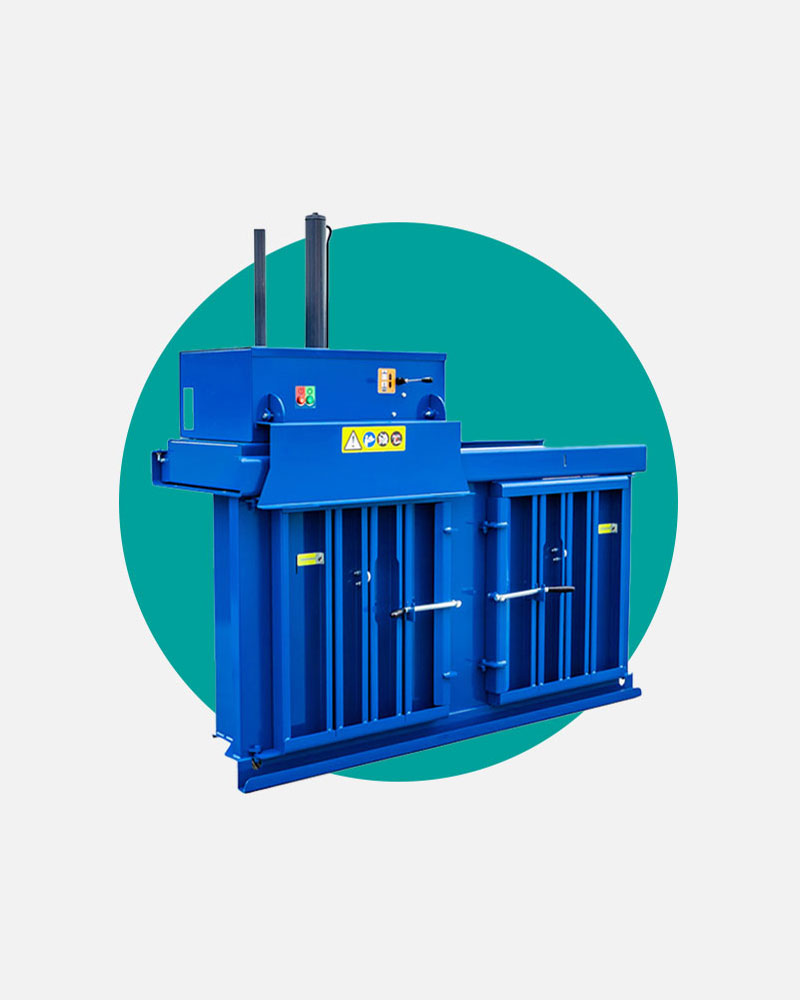

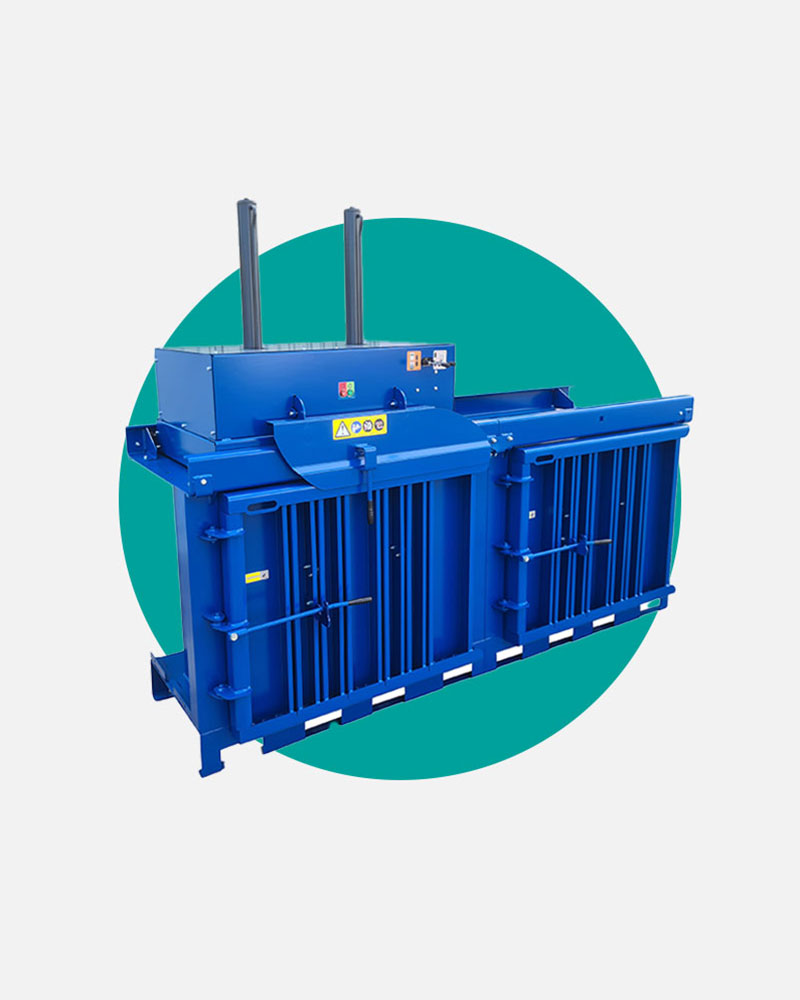

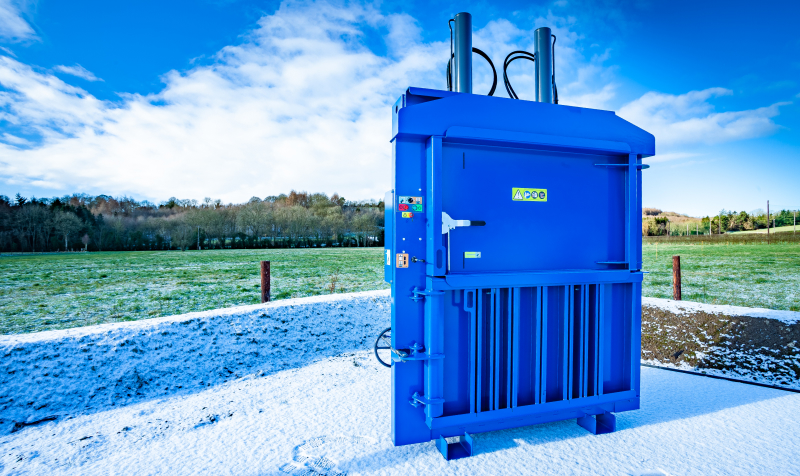

Our multi-chamber waste balers are the perfect solution for companies handling more than one waste stream. These flexible machines achieve an output similar to that of multiple waste balers, but with only one set of electric and hydraulic components you’ll keep maintenance and running costs to a minimum, and the upfront investment is at least 20% less than the cost of multiple units. Whether you’re looking for a twin baler, or a baling press with multiple chambers, talk to us about the material streams you handle, so we can help you make the best-fit investment.

Waste balers

What is a multi-chamber waste baler?

A multi-chamber baler is designed for businesses that generate different types of recyclable waste and want to keep them separate during the baling process. With multiple chambers that can be loaded and compacted independently, these machines make it easy to manage cardboard, plastic, and other recyclables without the need to switch materials between cycles.

They’re ideal for sites where space is limited but multiple waste streams are produced—offering a tidy, efficient, and time-saving solution.

By input

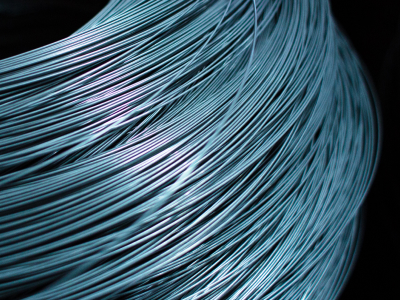

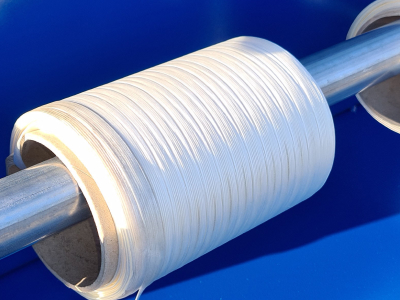

What materials does it bale?

Multi-chamber balers are commonly used to bale cardboard, plastic packaging, and paper—materials typically found in retail, warehousing, and industrial environments. If you have a different material in mind, we're happy to advise on suitability. Please get in touch with us to discuss your specific requirements.

Discover more

Benefits of a multi-chamber waste baler

01

Cost-effective for handling multiple waste streams

With separate chambers for different materials, you won’t need multiple machines to manage cardboard, plastic, and paper. This reduces capital spend and helps keep your recycling process efficient and streamlined.

02

Saves time and improves workflow

There’s no need to stop and switch materials between bales. Staff can load different chambers as needed, allowing continuous use and cutting downtime—ideal for busy environments.

03

Small footprint, big impact

Multi-chamber balers are designed to do the job of two or more machines in a single compact unit. Perfect for sites where space is limited but waste volumes are high.

04

Keeps waste streams separate and compliant

By baling each material type in its own chamber, you stay on the right side of recycling regulations and help avoid contamination—making your waste easier to sell or recycle.

05

Environmentally responsible

Better waste separation and efficient compaction mean fewer collections, reduced transport emissions, and a more sustainable approach to handling recyclable materials—helping you meet your environmental targets.

06

Cleaner, more organised workspace

No more overflowing bins or mixed recyclables piling up. A multi-chamber baler helps keep your waste area tidy and under control, giving a more professional appearance.

Featured product

RWM 500

Looking for a robust mill size baler? Commonly used as a cardboard or plastic baler for packaging waste, this tried-and-tested machine is actually suitable for an array of dry recyclables. With a large loading aperture it can easily handle large volumes of waste, and will produce bales that maximise transport efficiencies and load capacities.

Cardboard

Plastics

Paper

Film

"SWM are committed to safety, which is one of the key factors in sustaining relationships with suppliers and contractors – that’s why Riverside Waste Machinery Ltd has been servicing our internal balers successfully for a number of years. We recently needed to purchase a tipping skip and – despite not being advertised on their website at that time – Riverside happily provided a quote, which we accepted, and delivery was made promptly after."

Rebecca Howlett

SWM international