Service and maintenance

Waste baler servicing

What's included with service and support?

It is an overused phrase, and a bit of a cliché, but the age-old saying ‘prevention is cheaper than cure’ really is true. Just as we send our cars to be routinely inspected by mechanical experts to ensure they are in correct working order, we should adopt the same proactive approach to looking after waste balers too.

Service & maintenance

Regular servicing

As standard, we recommend a bi-annual service so that the same engineering experts who have installed your waste baler, can come and give it a thorough inspection twice a year before the unexpected happens! That said, talk to us about your baler usage, as we may advise a different servicing frequency better suited to your operations.

Very much a machinery health check, a baler service strives to optimise the ongoing performance of your equipment. We look for evidence of wear and tear, and dig deep to uncover any indications of potential future problems. We call this approach ‘preventative maintenance’. This reduces the likelihood of any unplanned downtime and minimises the future expenditure required to undertake potentially costly repairs. This servicing expertise is available throughout the UK, and on any waste baler regardless of the manufacturer.

Service & maintenance

Operator training

By design, our waste balers have been engineered so that they’re easy to use. That simplicity also extends to the maintenance – in fact, as part of the operator training we deliver at the commissioning stage, we advise a number of quick steps that clients can undertake to keep their equipment running smoothly.

Did you know we offer refresher training too, to ensure operators maintain their knowledge and certified competence?

Help & support

Aftersales care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.

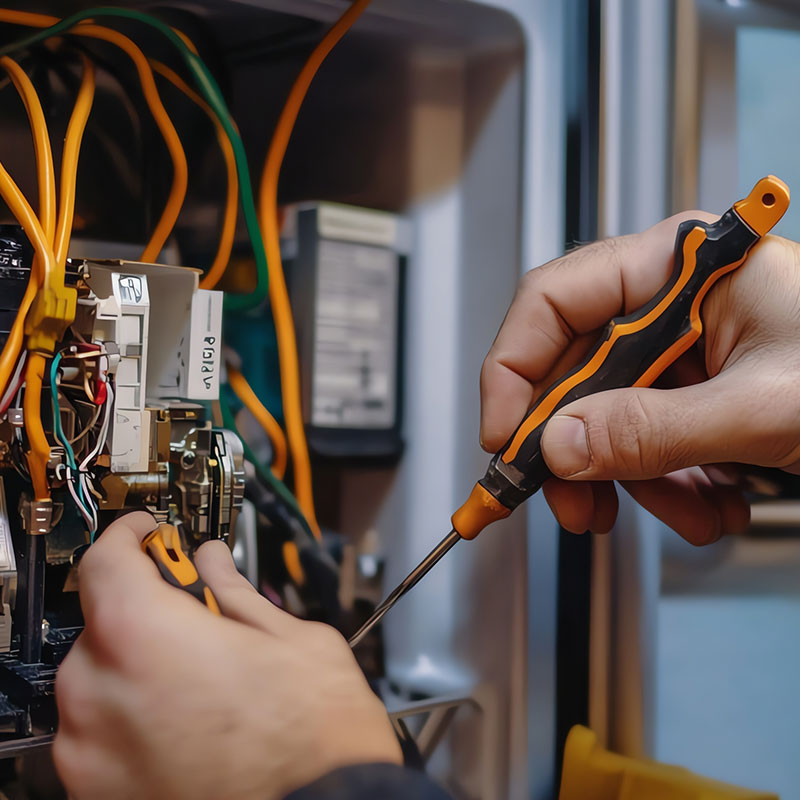

Baler repairs

If you don’t have a maintenance or service agreement in place, we can still help with any repair requirements that you have. Our specialist engineers will aim to resolve the problem as quickly and cost-effectively as possible, before leaving you with advice to help prevent any recurring faults or future technical problems.