RWM HZ500-38T

Overview

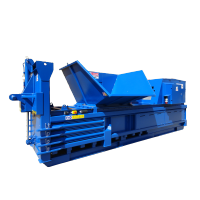

RWM HZ500-38T Horizontal Waste Baler

For businesses producing higher volumes of waste or recyclables, the RWM HZ500 offers the perfect balance of efficiency, performance, and ease of use. Horizontal semi-automatic balers are a popular step up from vertical models, delivering faster throughputs, heavier bales, and less manual input.

The RWM HZ500 is designed with flexibility in mind, capable of handling a wide variety of dry recyclables such as cardboard, paper, and more. With multiple in-feed options, minimal cycle times, and heavy bale weights, it’s built to keep pace with demanding environments. For added convenience, the machine is fitted with intelligent ‘magic eye’ sensors, which automatically trigger the compaction cycle to maximise productivity and minimise operator effort.

Perfect For:

-

Cardboard

-

Paper

-

PET Bottles

-

Light Plastics

-

Dry Recyclables

38T

Press force

6,500kg

Machine weight

60 sec

Cycling time

Technical specification

Pressing force

38 tonnes

loading aperture

1250 x 1050mm

(W x D)

bale weight

up to 500kg

Bale dimensions

750 x 1100 x 1200mm

(H x W x D)

noise level

80 decibels

machine weight

6,500kg

cycle time

60 seconds

overall dimensions

2550 x 2120 x 5855mm

(H x W x D)

Key Features

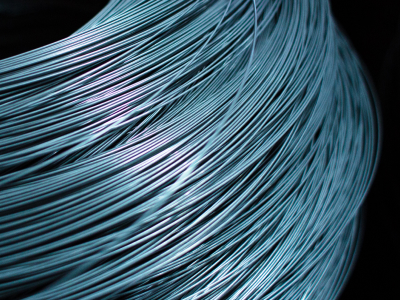

The RWM HZ500 is designed with efficiency, safety, and flexibility at its core. Its horizontal wire tie system allows wires to be threaded safely at ground level, removing the need for operators to climb onto the machine and significantly reducing risk. A Portcullis bale ejection door ensures smooth and reliable bale discharge, keeping downtime to a minimum.

Powered by an energy-efficient 5.5kW motor, the HZ500 delivers strong performance while keeping energy costs under control. The baler can be tailored to suit different waste streams and site setups, with optional feed methods such as conveyor loading or an 1100-litre bin lifter for easier handling of recyclables. For operations that require higher throughputs, faster cycle time options are also available.

Fitted with intelligent ‘magic eye’ sensors, the machine automatically starts and stops the compaction cycle, boosting productivity while reducing manual input. Producing dense, heavy, mill-size bales, the HZ500 ensures maximum payload efficiency for storage and transport. Built for reliability and capable of handling a wide range of materials – from cardboard and paper to plastics – it’s a robust choice for businesses dealing with higher volumes of recyclables.

"Riverside have provided us with excellent advice and robust and reliable products in the past, so I knew just who I wanted to speak to discuss our new requirements. They are extremely knowledgeable and I fully trusted the HZ 70T solution they put forward. Like all good facilities managers I did double check my options to make absolutely sure we were getting the right advice and best deal! I’m pleased to say though that Riverside’s initial advice was spot on."

Bahram Farboud

Facilities Manager, Unisurge International

Discover more

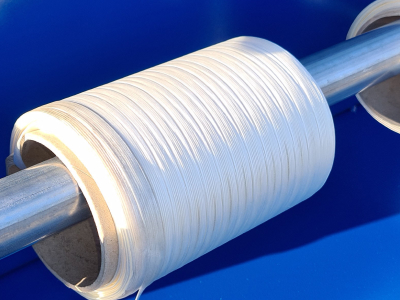

Related consumables

12 month warranty

For parts & labour as standard

20+ years experience

Supplying robust waste machinery

Rated 5/5 on Google

Great customer service

Buy, rent or hire

On all machines

Help & Support

Aftersales care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.