RWM Bag Press

Product Overview

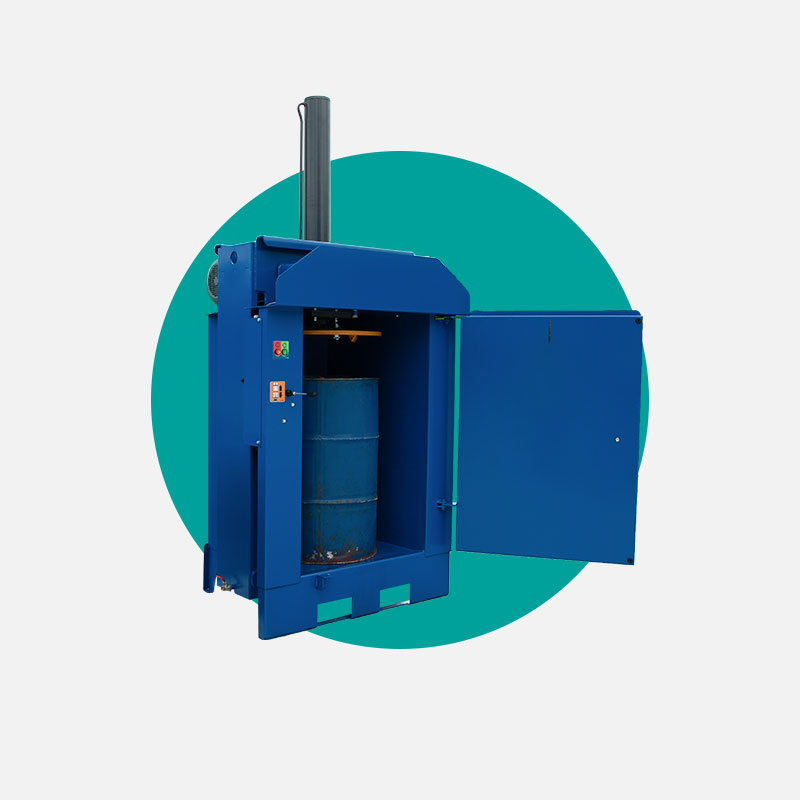

The Bag Press

A popular and cost-effective way to reduce your waste volumes by up to 90%, this proven bag press technology is perfect for both dry and wet recyclables (including food and kitchen waste). With simple-to-use controls, the machine quickly compresses materials into manageable sealed bags. The result is less mess, more space and – with fewer waste collections required – impressive financial savings.

Boasting a small footprint, the bag press is a neat addition to a garage forecourt, hotel, retail outlet, university or small hospitality establishment – to name just a few. Suitable for indoor or outdoor relocation, it is supplied with a 12 month warranty for maximum peace of mind.

Perfect For:

-

Wet Waste

-

Dry Recyclables

3T

Press force

325kg

Machine weight

20 sec

Cycling time

Technical specification

Pressing force

3 tonnes

Cycle time

20 seconds

Noise level

68 decibels

Machine weight

325kg

Compaction ratio

10:1

Power supply

13 amp 1.5kW-23-V-50Hz

Overall dimensions

1861 x 1200 x 630mm

(H x W x D)

Bag dimensions

175 x 520 x 1000mm

(H x W x D)

RWM Bag Press

Key Features

- High compaction ratio of up to 10:1

- Low operational height with top loading for ergonomic use

- Straightforward controls but operator training provided as standard

- Split chamber for simple bag removal

- Wheel mounted for ease of relocation, indoors or outdoors

- Supplied with 12 months parts and labour warranty

- Great for food/kitchen waste and other wet/dry recyclables

- A small footprint for space-constrained sites

"Our machine is a wonderful piece of kit, and we have had no issues whatsoever with it since it was installed."

Mark Blamire

Production Controller, Metamark UK Ltd

12 month warranty

For parts & labour as standard

20+ years experience

Supplying robust waste machinery

Rated 5/5 on Google

Great customer service

Buy, rent or hire

On all machines

Help & Support

Aftersales Care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.

People also liked...