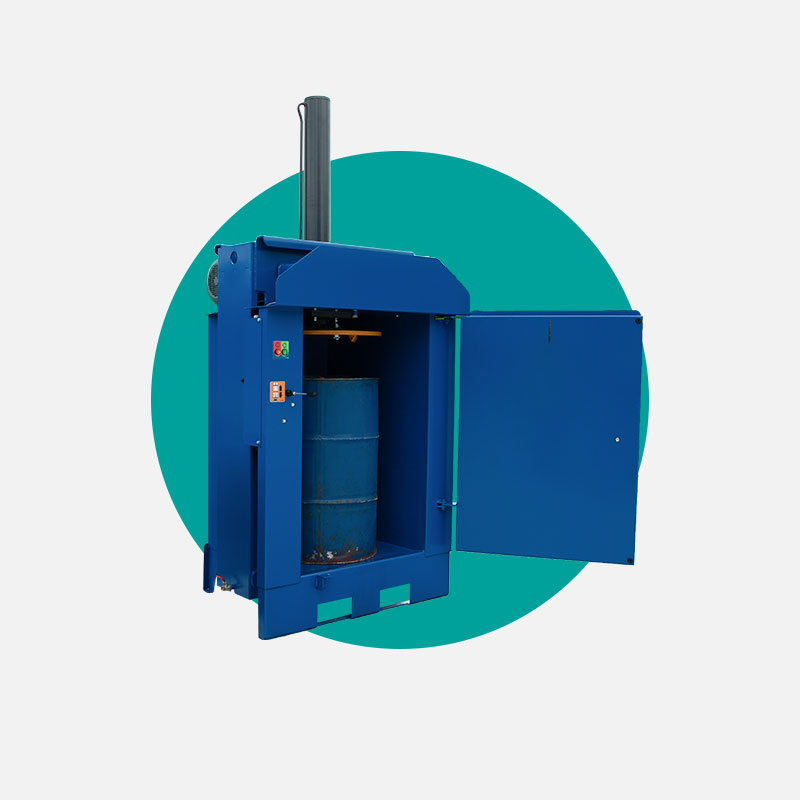

RWM Drum Press

Overview

The RWM drum press

This compact drum press may be a neat waste handling solution, suitable for indoor or outdoor use. But packed into this tidy hydraulic equipment is a 24 tonne compaction force that can crush light steel drums or rolling hoop barrels of up to 205 litres. Designed to revolutionise your approach to waste handling, this drum press even collects residual fluids discharged during compaction. The 30 litre collection tank can simply be drained through an integral tap, when full. This technology has been engineered to reduce organisations’ waste management costs and storage constraints. Suitable for businesses of all types and sizes, the drum press is available to purchase or rent, ensuring an affordable waste machinery solution whatever your cash flow or capital availability.

Perfect For:

-

Drum

24T

Compaction force

690kg

Machine weight

40s

Cycle time

Technical specification

Press Force

24 tonnes

Cycle Time

40 seconds

Noise Level

68 decibels

Machine weight

690 kg

Power Supply

32 amp 3 phase 11kW-400V-50Hz

Overall Dimensions

2587 x 1190 x 1000mm

(H x W x D)

Optional Transportation Height

1800mm

Compaction Ratio

10:1

12 month warranty

For parts & labour as standard

20+ years experience

Supplying robust waste machinery

Rated 5/5 on Google

Great customer service

Buy, rent or hire

On all machines

RWM Drum Press

Key Features

- 12-month warranty

- 24 Tonne press force

- Compaction ratio up to 10:1

- Suitable for up to 210L barrels

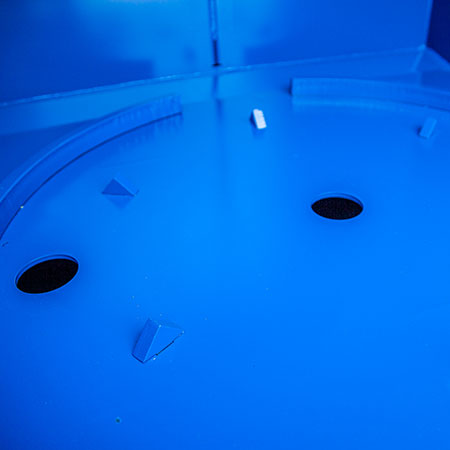

- 30-litre residual liquid collection tray with tap connection

- Clear controls for easy operation

- Totally enclosed shell ensures a high level of safety

- Can be sited outside

- 32amp 3 phase electrics

- CE marked

"Riverside’s price was very reasonable, and the robustness of the company’s products and customer service came highly recommended."

Mike Smith

Owner, Mida Sign Services

Help & support

Aftersales care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.