News

What are the current regulations surrounding packaging waste, and how do I comply?

In recent years, there has been growing concern around the environmental impact of packaging waste, particularly in the business sector. As a result, governments all over the world have introduced regulations to help reduce the amount of refuse generated by organisations.

For the UK, the regulations were first launched in 1997 in Great Britain. These became the Producer Responsibilities Obligations (Packaging Waste) Regulations 2007. This later version is still in place today.

These regulations often require firms to follow specific guidelines for disposal, as well as set targets for reducing their waste output. For example, in the European Union, the Packaging and Packaging Waste Directive sets targets for the recovery and recycling of packaging waste, with penalties for businesses that fail to comply.

One of the primary reasons for the introduction of packaging waste regulations is to reduce the amount of waste that ends up in landfill. This not only helps to preserve limited space, but also minimises greenhouse gas emissions generated by waste decomposition. By implementing these regulations, businesses are encouraged to prioritise waste reduction and recycling, while also promoting sustainable practices. For example, businesses may be required to use packaging materials that are recyclable or biodegradable, or to invest in recycling facilities, machinery, and programs to help reduce their overall waste output.

Who needs to comply?

If a company has an annual turnover of £2 million or more, and handles over 50 tonnes of packaging per year, it is required to comply with the Packaging Waste Regulations in the UK. This applies to various types of businesses, including manufacturers, sellers, importers, and those using packaging for transportation or storage purposes.

Understanding the regulations

It’s important to note that regulations may vary depending on the region or country, but the overall objective remains the same —to ensure companies take responsibility for managing and disposing of packaging waste in an environmentally sustainable manner. Compliance is crucial for companies involved in packaging activities to minimise their impact on the environment and contribute to a more sustainable future.

How can a waste baler help?

One such solution is waste balers, which offer a range of advantages for companies striving to manage and dispose of packaging waste in an environmentally sustainable manner. Here’s how:

1. Reduced waste volume

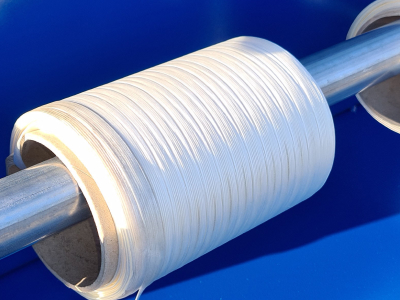

Waste balers have the remarkable ability to compress packaging waste, reducing its volume by up to 90%. This means that companies can store more waste in smaller areas, resulting in reduced storage costs and freeing up valuable space for other purposes. With waste balers, businesses can efficiently manage their packaging waste without it becoming a space-consuming burden.

2. Improved recycling

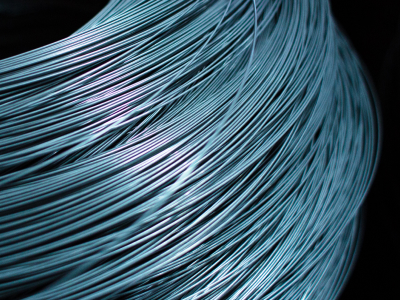

Sorting and separating different types of packaging waste, such as cardboard, plastic, and metal, is made easier with waste balers. By compacting and organising these materials, balers simplify the recycling process and reduce the amount of waste that ends up in landfills. This helps companies enhance their recycling efforts and minimise their environmental impact.

3. Cost savings

Waste balers deliver cost savings in multiple ways. By reducing volume, companies can decrease their waste disposal costs significantly. Additionally, compacted materials can be sold to recycling companies, creating new revenue streams for businesses. Waste balers prove to be a financially savvy investment that pays off in the long run.

4. Compliance

By utilising balers, companies effectively manage and dispose of their waste in an environmentally sustainable manner. This proactive approach helps organisations avoid fines and penalties associated with non-compliance, while demonstrating their commitment to responsible waste management.

5. Safety

Waste balers contribute to workplace safety by reducing the need for manual handling of heavy and bulky waste materials. This diminishes the risk of workplace injuries and promotes a safer working environment for employees. Balers automate the process, allowing workers to focus on other tasks that require their expertise.

6. Environmental impact

Embracing waste balers enables companies to reduce their environmental impact significantly. By reducing waste volume and improving recycling rates, businesses can demonstrate their commitment to sustainability and environmental stewardship. This resonates with customers and stakeholders who prioritise eco-conscious companies, enhancing a firm’s’s reputation and attracting environmentally conscious clientele.

Ultimately, packaging waste regulations provide an important framework for businesses to operate in a more sustainable and environmentally responsible manner, helping to preserve our planet for future generations. And waste balers provide companies with an efficient and effective solution to comply with such frameworks, while reaping numerous benefits. From reducing waste volume and improving recycling rates to generating cost savings and enhancing workplace safety, waste balers have become an indispensable tool for businesses striving for environmental sustainability.