Services & Support

Service and support

We’re so much more than just a waste baler supplier. We’re here to help.

With decades of collective recycling and waste management experience, our specialist engineers and consultants are often called upon for their wider services, knowledge and support.

So whether you’re looking for a spot of waste handling guidance, some machinery maintenance or a related spare part or consumable, why not see if we can help you?

How can we help you?

Our Shop

Shop our extensive range of waste baler consumables

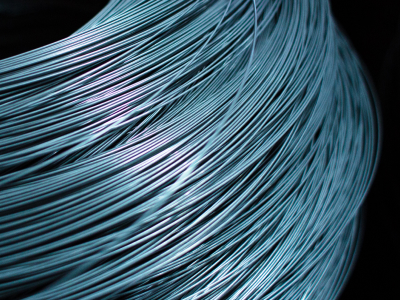

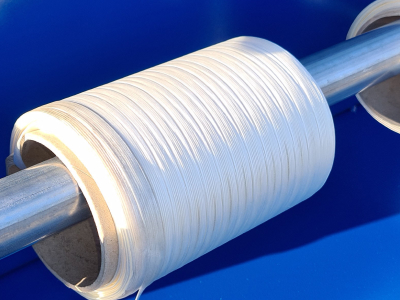

In addition to industry-leading waste machinery, Riverside also offers an extensive range of competitively-priced waste baler consumables including baling twine, baling tape and baling wire. We guarantee you won’t find a cheaper like-for-like quote anywhere else in the industry.

"We’re extremely pleased with the all-encompassing service provided by Jonathan and his team, which even includes the collection of our baled materials."

Tom Reid

Operations Manager, Tech Buyer