About baler

Take control and convert your dry recyclable packing waste into manageable bales. Recyclers and industrial users of a Riverside vertical baler benefit from waste volume reduction; storage, handling and transportation savings; avoidance of ever-increasing landfill charges; the satisfaction of environmental benefits and even possibly the generation of an additional revenue yield.

Spec

Key Features

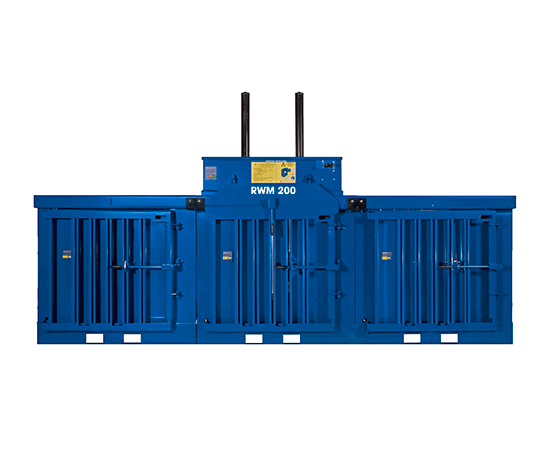

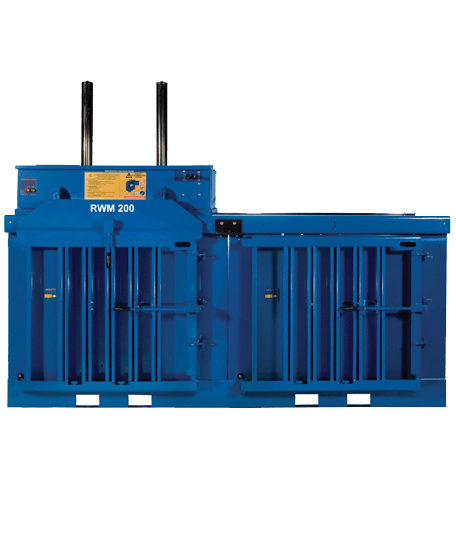

Depending upon client requirements the RWM 200 can be supplied with two, three or four baling chambers. The RWM 200 twin for instance enables users to bale two types of materials whilst utilising only one set of electric and hydraulic components. This achieves an output similar to that of two balers, but keeps maintenance and running costs to a minimum.

Please note: the video is for illustration purposes only and doesn’t represent a true scale operation.

“This is the first time we’ve used Riverside but we wouldn’t hesitate to work with them again because they treated us in such a courteous manner. The new baler is incredibly efficient and the price was very competitive too.”

Derek Armstrong, Stores Director, GW Proudfoot

Our Aftersales Care

A number of organisations – especially those making the first step to improve their waste handling capabilities – are a little apprehensive about what happens after their investment in a waste baler. What if their plant manager gets a new job and there’s a knowledge gap? What if they make a mistake and a small repair is needed? These worries are perhaps natural, but there’s really nothing to panic about.

Firstly, our waste balers are incredibly easy to use, but secondly, our baling engineers will be with you every step of the way, long after the initial procurement. Providing training, service and maintenance expertise, spare parts or simply a waste handling review, we’ll help you maximise the return from your investment, for years to come.

Read More